Challenges of Moving Products Outside

- Uneven Terrain: Outdoor environments often have uneven surfaces, such as gravel, grass, or dirt, which can make it difficult to move products smoothly.

- Weather Conditions: Adverse weather conditions like rain, snow, or strong winds can create additional challenges for outdoor material handling, affecting load stability and posing safety risks.

- Increased Distance: Moving products between buildings or across large outdoor spaces may require covering long distances, resulting in physical strain for workers.

- Obstacles and Curbs: Outdoor areas may have curbs, ramps, or other obstacles that can impede the movement of traditional dollies.

- Load Protection: Products transported outdoors need protection from elements and potential damage, which can be challenging with standard dollies.

Challenges Traditional Dolly Carts Face When Moving Items Outside:

- Traction Issues: Traditional dollies with standard casters may encounter traction issues on rough outdoor surfaces, reducing stability and making it harder to push or pull loads.

- Limited Terrain Adaptability: Standard dollies may struggle to navigate efficiently over diverse outdoor terrains, leading to slower movement and potential tipping.

- Weather Resistance: Regular dollies may not be designed to withstand exposure to rain, dust, or extreme temperatures, resulting in wear and tear and decreased longevity.

- Load Security: Outdoor environments may require additional load security to prevent products from shifting during transport, which standard dollies may lack.

- Portability: Some traditional dollies may not be easily portable outdoors due to their design limitations or lack of adaptability to changing outdoor conditions.

Benefits of the Raised Safety Dolly for Outdoor Material Handling:

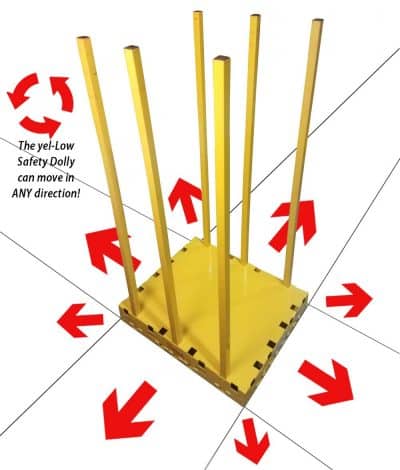

Seamless Outdoor Handling: The Raised Safety Dolly excels in outdoor material handling due to its unique features and design.

- All-Terrain Wheels: The dolly’s wheels mounted to the corners and locking casters offer excellent traction and maneuverability over various outdoor terrains, ensuring smooth movement.

- Weather-Resistant Materials: Built with durable and weather-resistant materials, the Raised Outdoor Safety Dolly can withstand exposure to outdoor elements without compromising performance.

- Enhanced Stability: The dolly’s locking casters and bracket support provide increased stability and load security, reducing the risk of tipping even on uneven surfaces.

- Easier Load Protection: The Raised Safety Dolly’s design allows for easier integration of load protection measures, such as straps or covers, to safeguard products during outdoor transport.

- Improved Portability: Its adaptability between indoor and outdoor configurations makes the Raised Safety Dolly easily portable, allowing for efficient material handling in both settings.

- Long-Lasting Durability: The dolly’s robust construction ensures it can withstand the challenges of outdoor use, providing long-lasting performance and value.

- Versatile Applications: With its ability to transport items between buildings, across outdoor spaces, and on construction sites, the dolly proves valuable in various outdoor applications.

- Time and Labor Savings: The Raised Safety Dolly’s efficiency in outdoor material handling reduces the time and physical effort required to move products across long distances.

- Safe Load Transportation: Its enhanced stability and braking system make the Raised Safety Dolly a safer choice for moving items outdoors, minimizing the risk of accidents and injuries.

- Overall Efficiency: By addressing the challenges of outdoor material handling, the Raised Safety Dolly contributes to improved efficiency, productivity, and worker satisfaction.

The Raised Safety Dolly overcomes the challenges of moving products outside with its all-terrain capabilities, weather-resistant materials, enhanced stability, and easy load protection. Its design advantages make it a reliable tool for efficient outdoor material handling, offering numerous benefits for various outdoor applications.

Continue Reading