Cutting corrugated plastic can present various challenges:

Precision Cutting: Corrugated plastic sheets require precise cutting to achieve accurate shapes and sizes for various applications.

Material Thickness: Corrugated plastic comes in different thicknesses, and cutting through thicker materials can be more challenging with standard tools.

Avoiding Fraying and Splintering: Traditional cutting methods may cause fraying and splintering of the corrugated plastic edges, affecting the overall finish and durability.

Material Strength: Corrugated plastic is durable, but using improper tools can lead to incomplete cuts or damage to the material.

Challenges Traditional Cutters Have with Cutting Corrugated Plastic:

Traditional cutting tools may face limitations when working with corrugated plastic:

Inaccurate Cuts: Standard cutters may result in uneven or imprecise cuts, leading to ill-fitting pieces and subpar results.

Limited Versatility: Some cutting tools may not be suitable for handling thicker corrugated plastic sheets, restricting their application.

Risk of Material Damage: Using the wrong cutting tool can damage the corrugated plastic, reducing its strength and compromising its integrity.

Strain on the User: Manual cutting with traditional tools can be physically demanding and cause strain on the user’s hands and arms.

Ergonomic Design Leverages the Blades Handle Grip to Cut Corrugated Plastic with Less Strain:

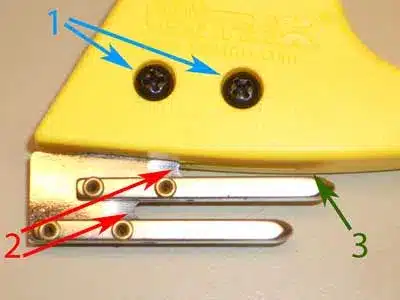

The Ergonomic Corrugated Plastic Cutting Coro Claw 4 mil flute cutter boasts an ergonomic handle design that takes cutting corrugated plastic to a whole new level of ease and comfort. This feature allows users to effortlessly achieve precise and clean cuts without straining their hands and arms.

Enhanced Comfort: The Coro Claw’s ergonomic handle design ensures a comfortable grip, reducing fatigue and discomfort during prolonged cutting sessions. By utilizing larger muscles in the back and shoulders, it minimizes strain on the user’s hands and arms, making cutting tasks more enjoyable and less taxing.

Improved Precision: The ergonomic design promotes a steady and controlled cutting motion, enhancing precision and accuracy. Users can achieve cleaner cuts, resulting in high-quality finished products for a wide range of applications.

Streamlined Workflow: With the Coro Claw’s ergonomic handling, users experience increased cutting efficiency. The effortless motion allows for faster completion of projects, saving valuable time and boosting productivity.

Versatile Application: The ergonomic handle design makes the Coro Claw suitable for users of all skill levels. From DIY enthusiasts to professionals, anyone can benefit from its user-friendly design for various cutting tasks.

Longevity and Endurance: The ergonomic handle design contributes to the cutter’s durability. It is built to withstand repeated use without compromising on performance, making it a reliable tool for the long haul.

Ergonomics for Everyone: The Coro Claw ensures that ergonomic advantages are accessible to all users. Whether working on large-scale projects or intricate details, the ergonomic design facilitates smooth and controlled cutting actions.

Reduced Risk of Injury: Traditional cutting tools can lead to repetitive strain injuries and discomfort. The Coro Claw’s ergonomic handle mitigates such risks, prioritizing user safety and well-being.

Efficient DIY Projects: For DIY enthusiasts working on creative projects, the ergonomic design of the Coro Claw eliminates physical strain, allowing them to focus on their artistic vision without distraction.

Professional Results: The ergonomic advantage translates to cleaner, more accurate cuts, resulting in professional-quality outputs for businesses and crafters alike.

Cost-Effective Solution: By reducing the risk of user fatigue and strain-related injuries, the Coro Claw 4 mil flute cutter provides a cost-effective solution, ensuring better productivity and consistent performance over time.

The ergonomic design of the Coro Claw 4 mil flute cutter makes cutting corrugated plastic an effortless and enjoyable process. With enhanced comfort, precision, and efficiency, this tool is a game-changer for various users, delivering high-quality results while ensuring user safety and comfort.

Continue Reading