Cutting and creating tote boxes or storage bins from corrugated plastic materials present specific challenges:

Precision and Consistency: Tote boxes and storage bins require precise cutting and uniform dimensions to ensure proper fitting and functionality.

Material Strength: Corrugated plastic must be cut with care to maintain its strength and durability, ensuring the tote boxes and bins can withstand heavy loads.

Customization: Different industries and applications demand various sizes and shapes of tote boxes and storage bins, necessitating flexible cutting capabilities.

Time-Sensitive: Industrial and commercial projects often have tight timelines, requiring efficient cutting to meet production deadlines.

Challenges Traditional Cutters Have with Cutting and Creating Tote Boxes or Storage Bins:

Traditional cutting tools may encounter limitations when working with corrugated plastic for tote boxes and storage bins:

Inconsistent Cuts: Traditional cutters may struggle to deliver consistent and precise cuts, leading to variations in dimensions and compromising the functionality of the boxes and bins.

Material Waste: Inefficient cutting can result in material waste, increasing production costs and impacting sustainability efforts.

Limited Versatility: Some traditional cutters may have limited capabilities, restricting the range of customization options for tote boxes and storage bins.

Cumbersome Setup: Traditional cutters might require complex setups or specialized training, further extending production time.

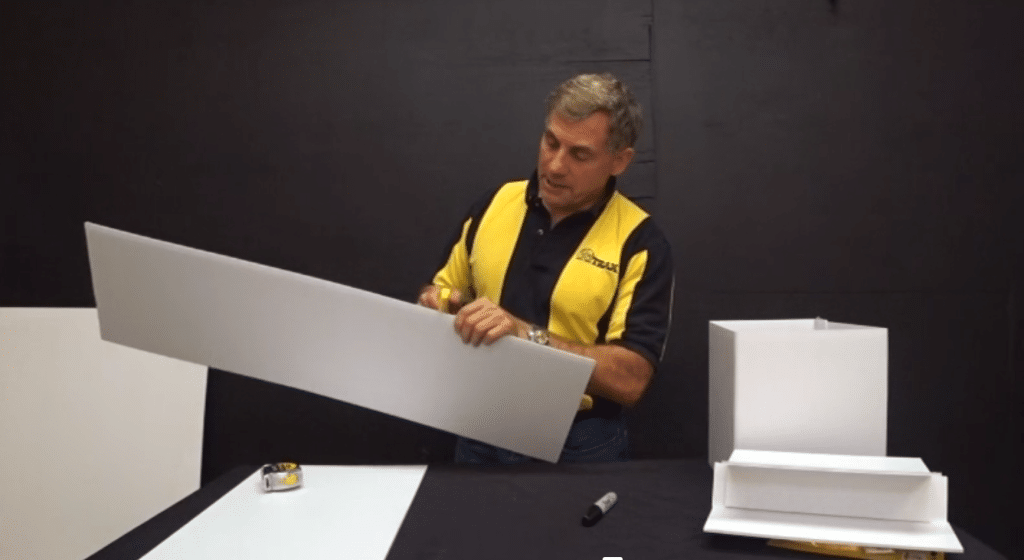

How the Coro Claw 4 mil Makes Cutting and Creating Tote Boxes or Storage Bins an Easy Process:

The Coro Claw 4 mil flute cutter offers several benefits to overcome the challenges of cutting and creating tote boxes or storage bins:

Precision and Efficiency: The Coro Claw’s sharp and adjustable blades ensure precise and consistent cutting, streamlining the creation of tote boxes and storage bins.

Material Integrity: The Coro Claw’s non-abrasive cutting action preserves the strength and durability of corrugated plastic, producing reliable and long-lasting tote boxes and storage bins.

Versatility: With its ability to handle 4 mil, 5 mil, and 6 mil corrugated plastic materials, the Coro Claw provides flexibility in creating custom-sized and shaped tote boxes and bins.

Cost-Effective Solution: The Coro Claw’s replaceable cutting heads enhance its longevity, making it a cost-effective choice for repetitive cutting tasks.

Reduced Material Waste: The precision cutting offered by the Coro Claw minimizes material waste, supporting sustainability efforts and reducing production costs.

User-Friendly Design: The Coro Claw’s ergonomic handle design reduces user strain and makes it easy to operate, enabling a smooth and efficient cutting process.

Versatility for Other Applications: Beyond tote boxes and storage bins, the Coro Claw’s capabilities extend to crafting boxes, making signs, and cutting display graphics, making it a versatile tool for various projects.

The Coro Claw 4 mil flute cutter excels in cutting and creating tote boxes or storage bins from corrugated plastic materials. With its precision, versatility, and cost-effectiveness, it ensures the efficient production of durable and customized storage solutions for industrial and commercial applications.

Continue Reading